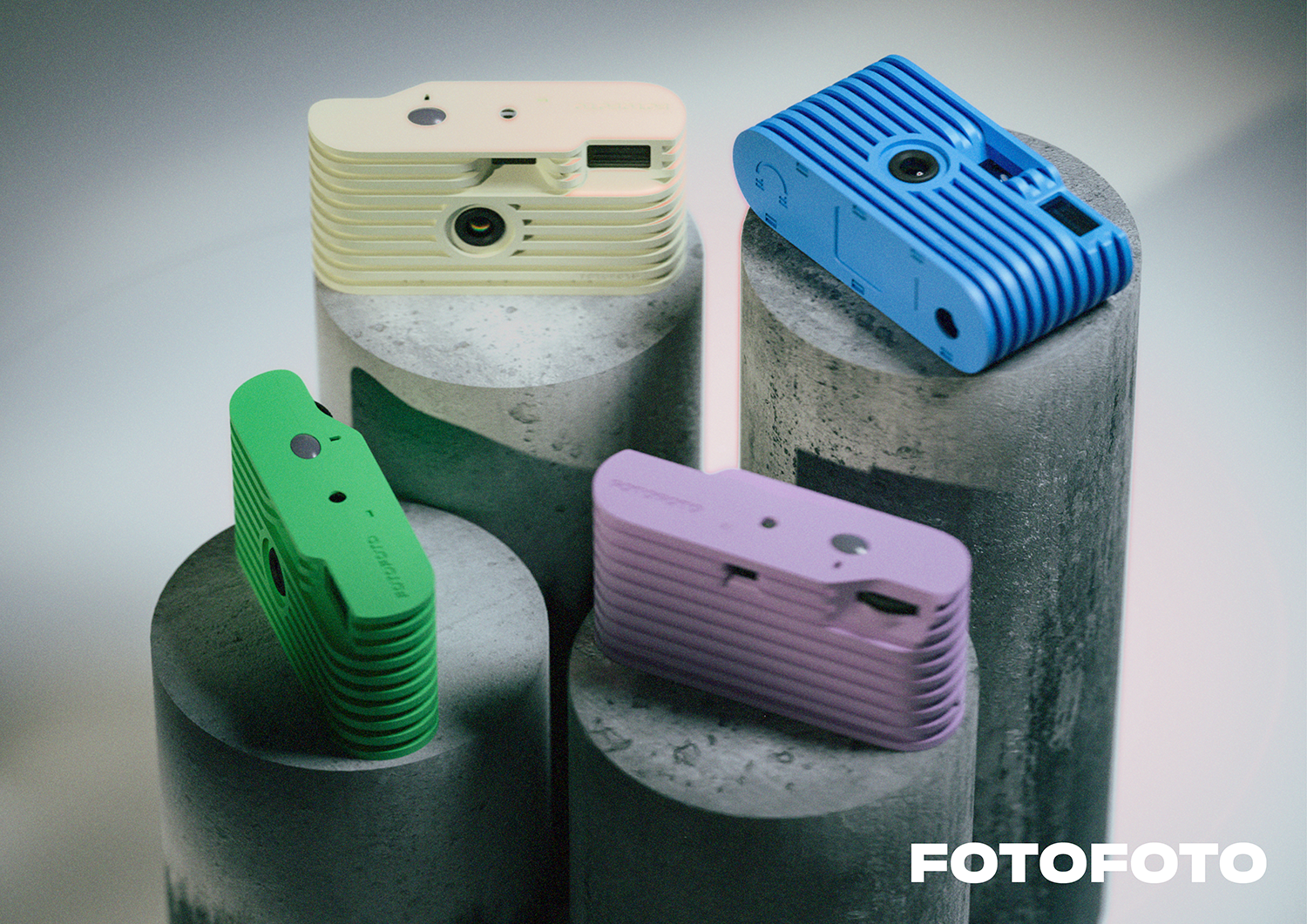

Fixing the Disposable Camera

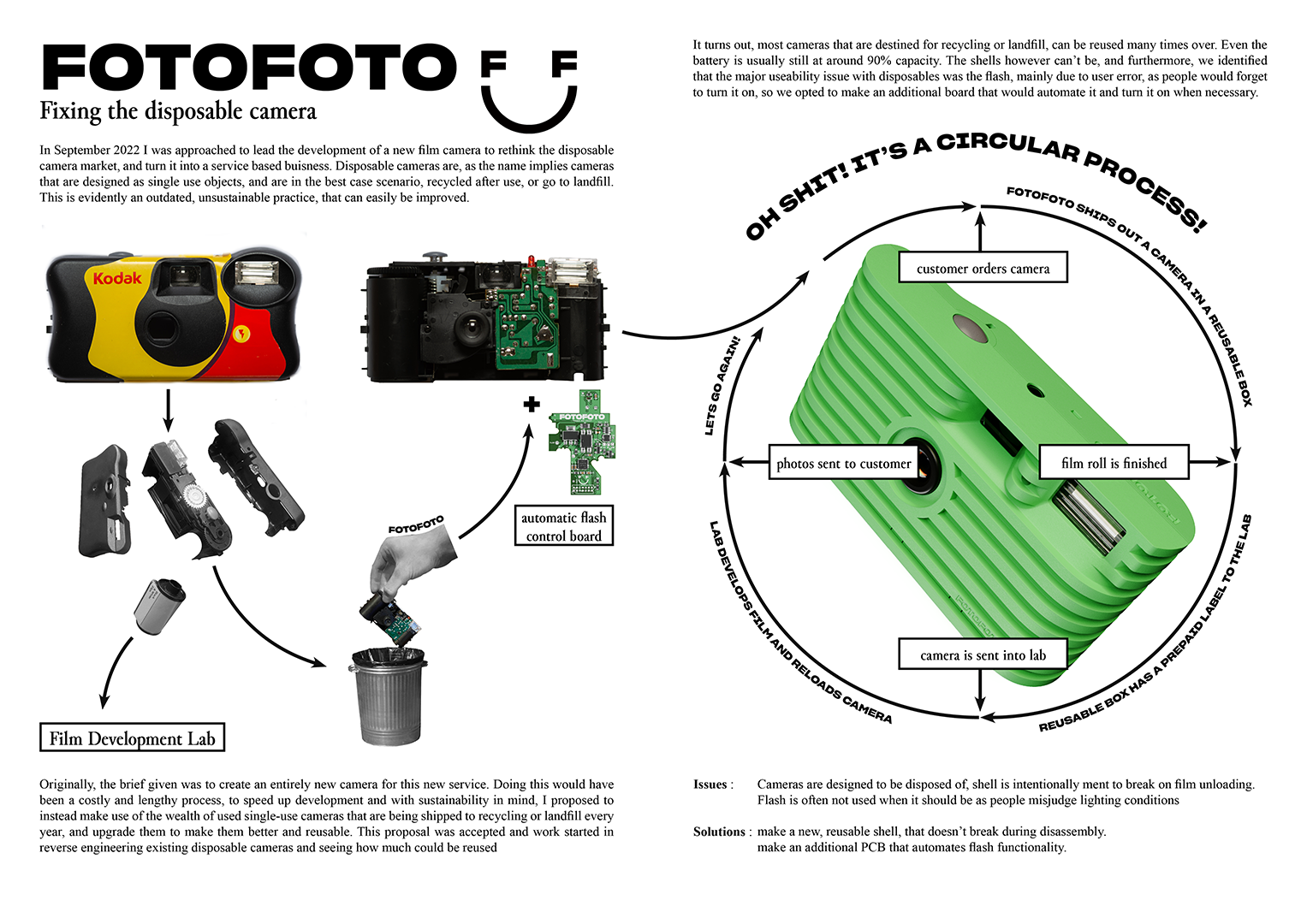

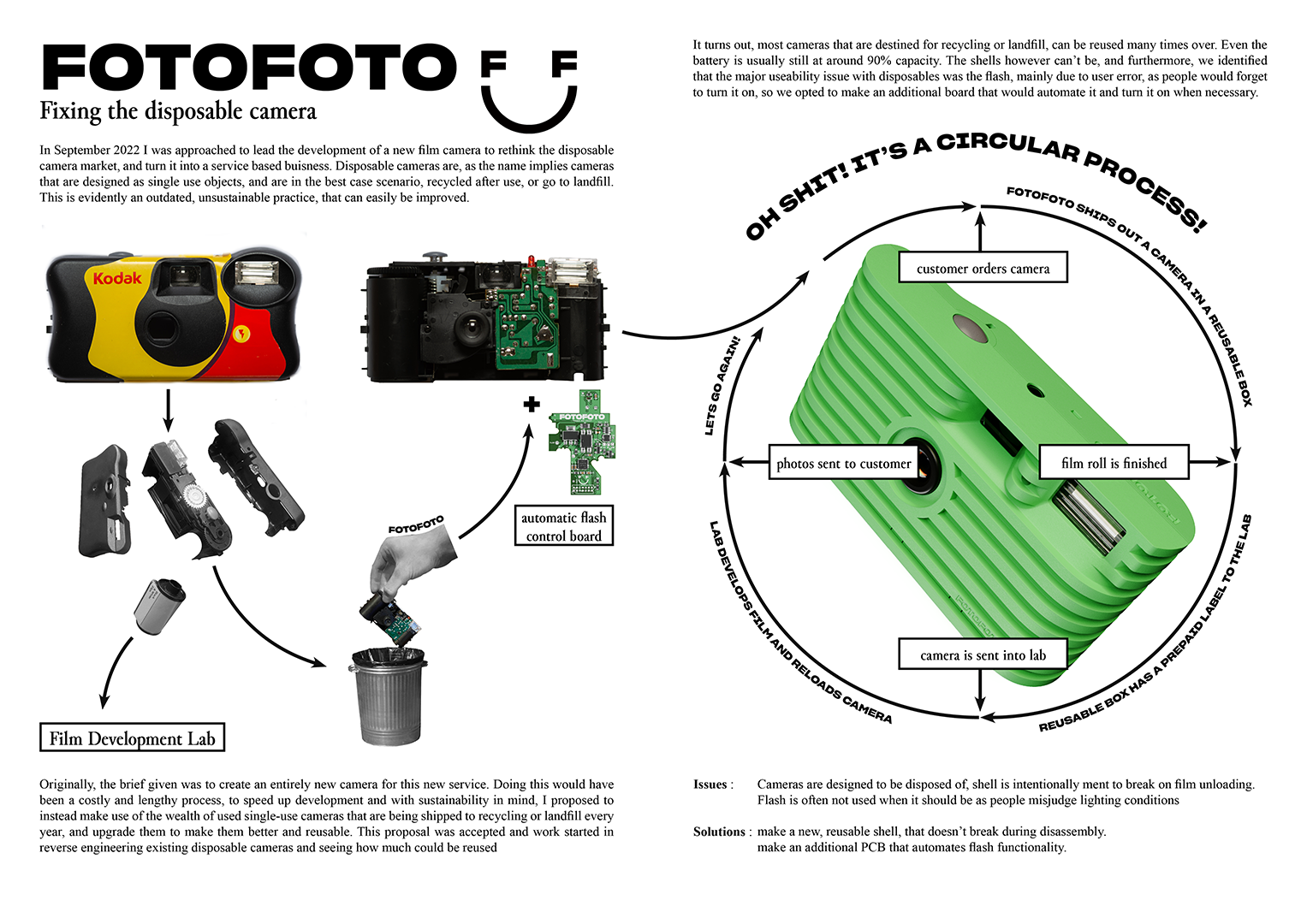

In September 2022 I was approached to lead the development of a new film camera to rethink the disposable

camera market, and turn it into a service based buisness. Disposable cameras are, as the name implies cameras

that are designed as single use objects, and are in the best case scenario, recycled after use, or go to landfill.

This is evidently an outdated, unsustainable practice, that can easily be improved.

Originally, the brief given was to create an entirely new camera for this new service. Doing this would have

been a costly and lengthy process, to speed up development and with sustainability in mind, I proposed to

instead make use of the wealth of used single-use cameras that are being shipped to recycling or landfill every

year, and upgrade them to make them better and reusable. This proposal was accepted and work started in

reverse engineering existing disposable cameras and seeing how much could be reused

It turns out, most cameras that are destined for recycling or landfill, can be reused many times over. Even the

battery is usually still at around 90% capacity. The shells however can’t be, and furthermore, we identified

that the major useability issue with disposables was the flash, mainly due to user error, as people would forget

to turn it on, so we opted to make an additional board that would automate it and turn it on when necessary.

Issues : Cameras are designed to be disposed of, shell is intentionally ment to break on film unloading.

Flash is often not used when it should be as people misjudge lighting conditions

Solutions : make a new, reusable shell, that doesn’t break during disassembly.

make an additional PCB that automates flash functionality.

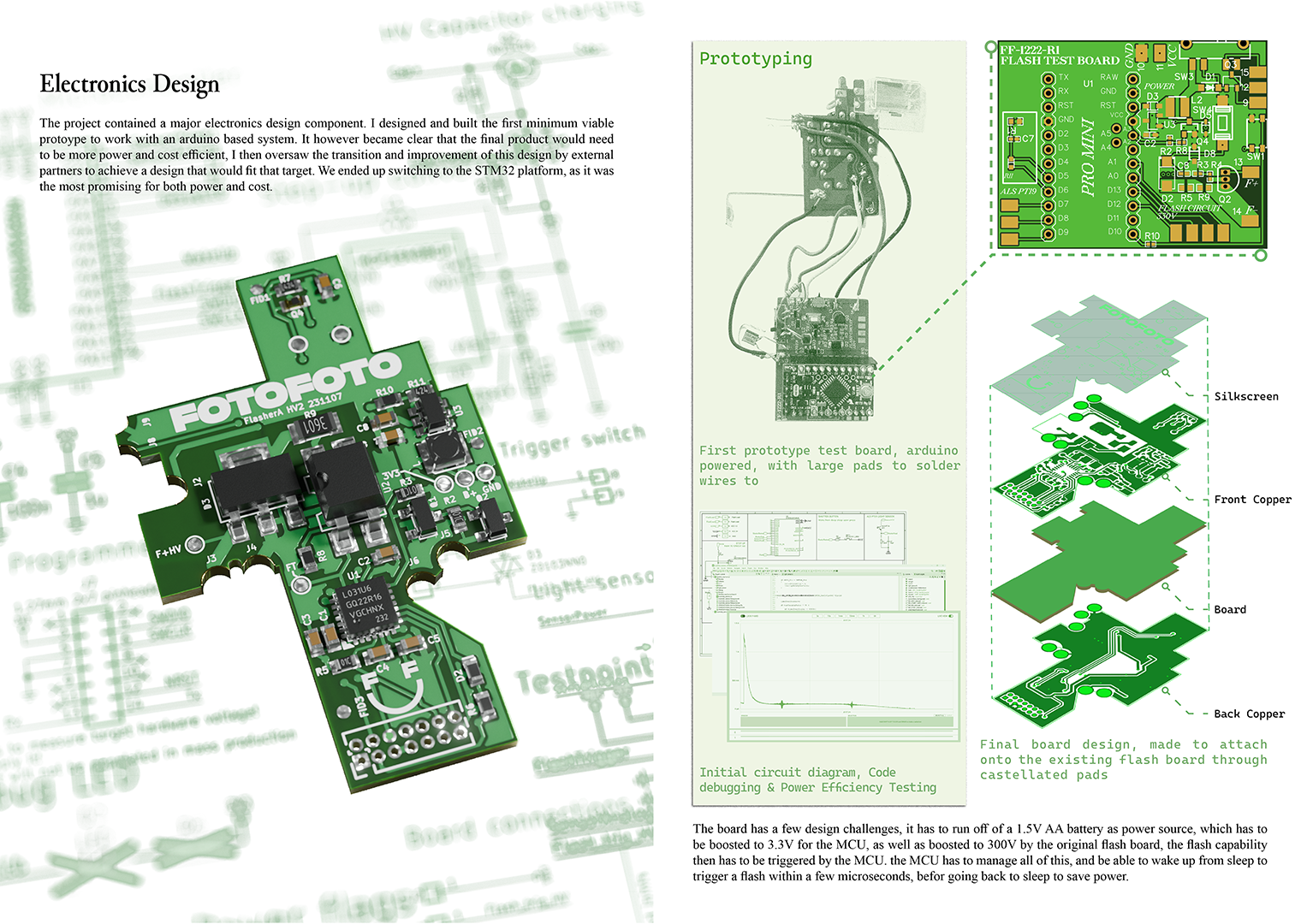

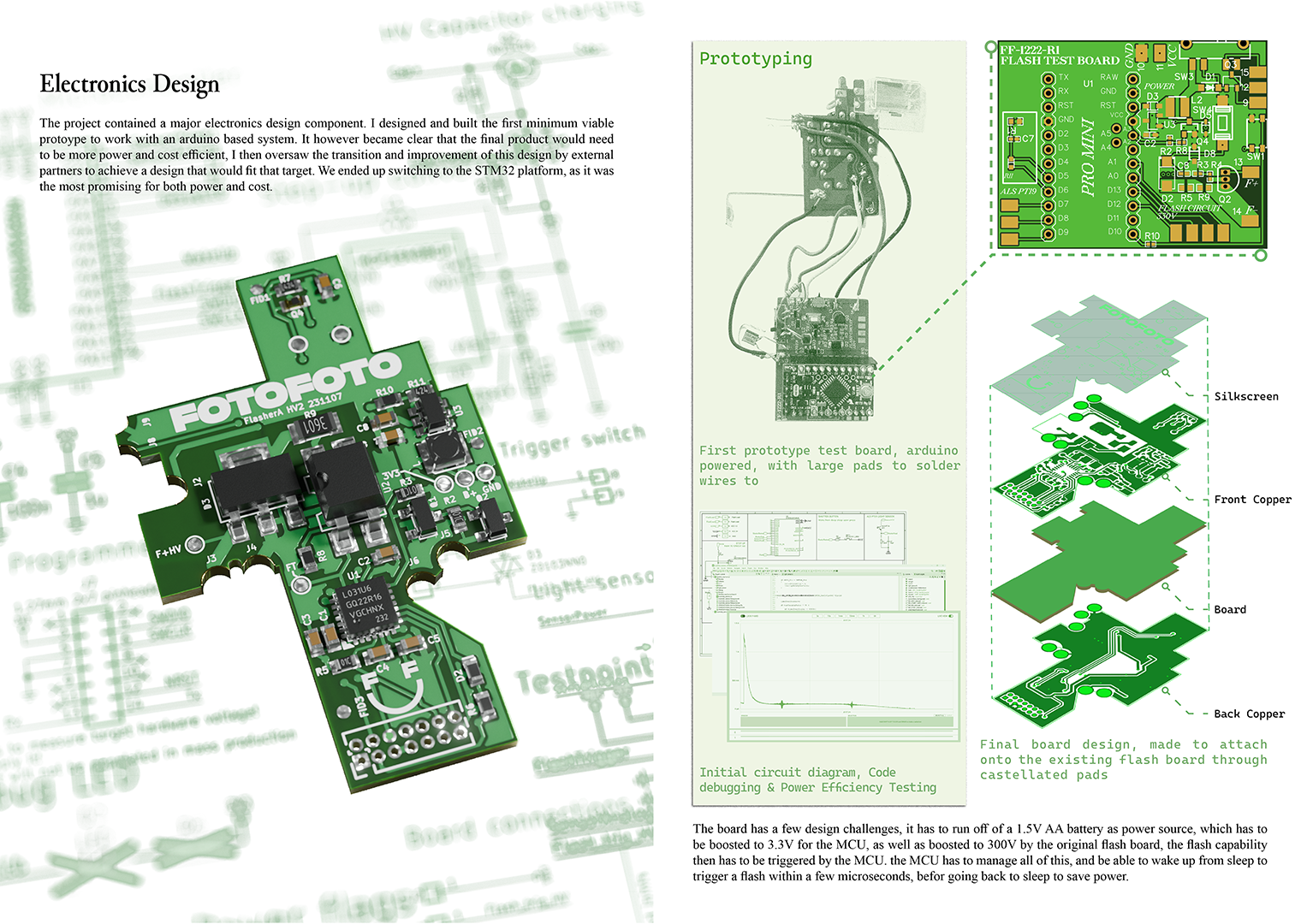

Electronics Design

The project contained a major electronics design component. I designed and built the first minimum viable

protoype to work with an arduino based system. It however became clear that the final product would need

to be more power and cost efficient, I then oversaw the transition and improvement of this design by external

partners to achieve a design that would fit that target. We ended up switching to the STM32 platform, as it was

the most promising for both power and cost.

The board has a few design challenges, it has to run off of a 1.5V AA battery as power source, which has to

be boosted to 3.3V for the MCU, as well as boosted to 300V by the original flash board, the flash capability

then has to be triggered by the MCU. the MCU has to manage all of this, and be able to wake up from sleep to

trigger a flash within a few microseconds, befor going back to sleep to save power.

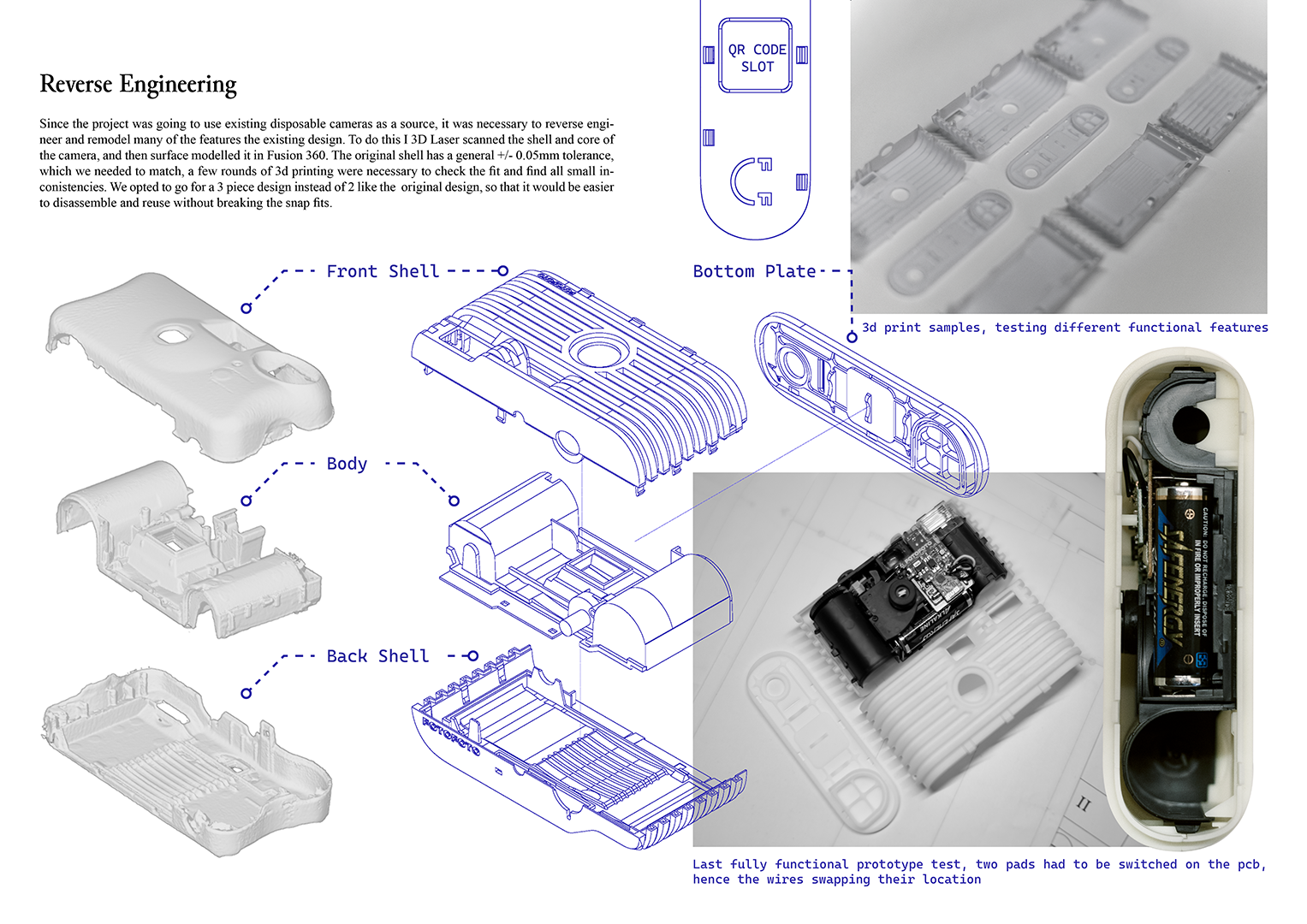

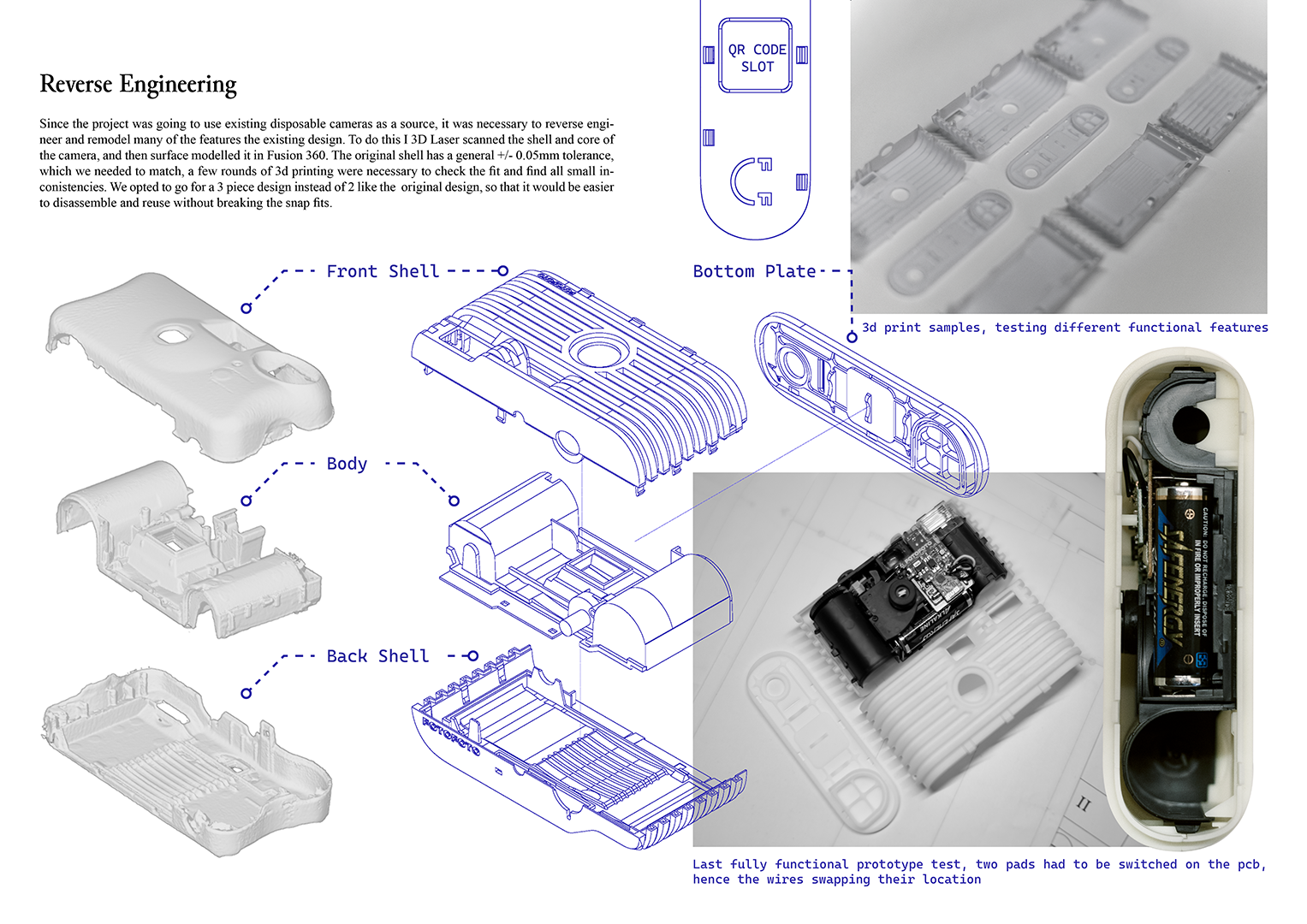

Reverse Engineering

Since the project was going to use existing disposable cameras as a source, it was necessary to reverse engineer

and remodel many of the features the existing design. To do this I 3D Laser scanned the shell and core of

the camera, and then surface modelled it in Fusion 360. The original shell has a general +/- 0.05mm tolerance,

which we needed to match, a few rounds of 3d printing were necessary to check the fit and find all small inconistencies.

We opted to go for a 3 piece design instead of 2 like the original design, so that it would be easier

to disassemble and reuse without breaking the snap fits.

Industrial Design

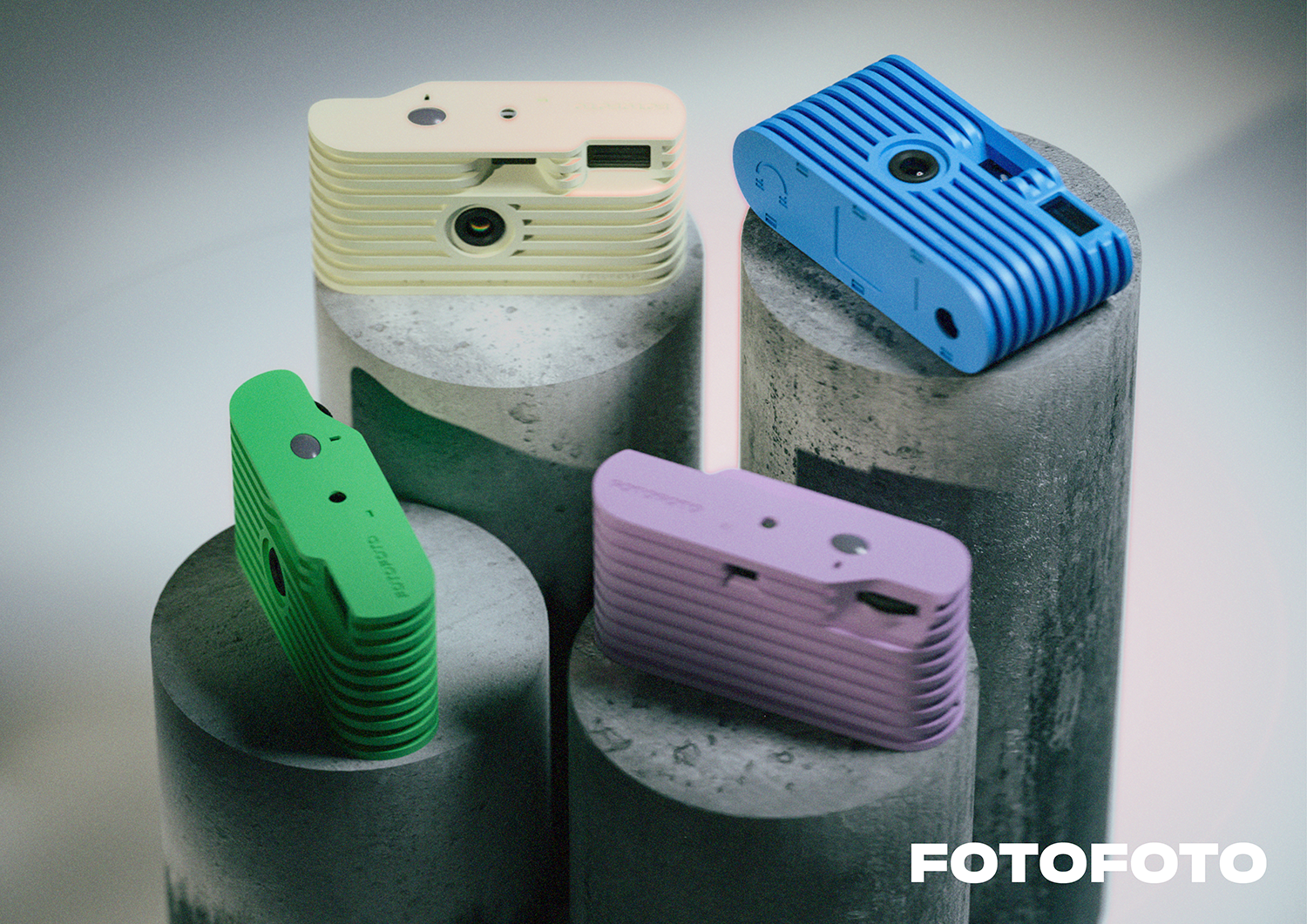

The project came to me with a first draft of the industrial design, and a firm idea of what they wanted, notably,

a design with strong linework, intended to be reminiscent of art-deco patterning. As such we worked on adapting

their design to the existing disposable cameras, while tweaking and simplifying some of the aesthetics to

make it more streamlined. A majority of the work was making the design functional for assembly and disassembly,

while retaining light-tightness and good resistance to the shell breaking if dropped.